F.O.G. Program

Fats, Oils, and Grease (FOG) regulations for Food Services Establishments (FSE)

ordinance_63.pdf

Spill Emergency Response Plan (SERP) 2023

Spill Emergency Response Plan (SERP) 2023.pdf

FOG Education Video

Español:

Tiếng Việt:

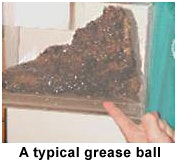

Fats, oils and greases (FOGs) are expected by-products of food preparation, whether on a large scale as found in the food industry, or the incidental amounts caused by residential cooking. When cooking fats, oils and grease are poured down the drain, they tend to collect and stick to household plumbing and sewer lines. Over time blockages occur that lead to sewer backups, sometimes causing sewage to overflow from plumbing fixtures or sewer system manholes.

Midway City Sanitary District Ordinance 63 prohibits “any wastewater having a fat waste, oil or grease (FOG) content, whether or not emulsified, from being discharged through the district sewer system. Greases and other food wastes can quickly accumulate and cause blockages in smaller pipes heavily used by food services.

Contributing to the blockage problem is the widespread use of products designed to emulsify wastes or otherwise clear drains of grease build-up. These products include biological and chemical treatment agents, and cleaners such as caustic and lye. While these products may clean or open your drains, they do not render the grease harmless; instead, once the grease moves downstream it tends to coagulate again. If this happens often enough, businesses or homes may experience expensive and inconvenient sewer back-ups. While emulsifiers and cleaners may clear pipes in the short term, they create larger and more expensive problems for you and your sewer utility in the long term.

To avoid future blockage problems, the Midway City Sanitary District has developed the FOG Program to educate food service providers on the proper practices for dealing with FOG. Proper practices include the use of grease interceptors and traps that are designed to remove FOG from the wastewater stream.

Grease Traps and Interceptors

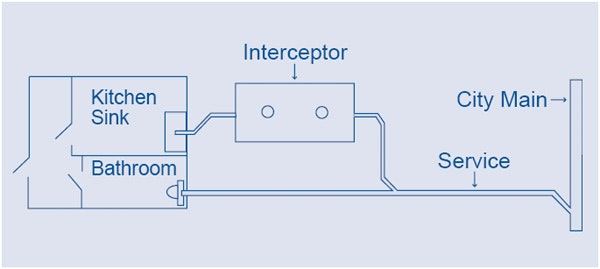

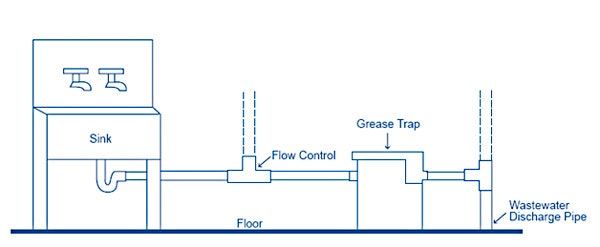

Grease traps and interceptors are two types of passive collection devices that protect sewer lines from blockages caused by excessive amounts of fats, oils and greases. These devices route wastewater from kitchen drains through the interceptor or trap, slowing the flow to allow heavier solids to settle to the bottom while fats, oils and greases float to the top. Grease will accumulate in the devices and allow relatively FOG-free water to flow from the device into the sanitary sewer system. To be effective, grease interceptors and traps must be installed according to the manufacturers’ specifications by a certified installation service. The Uniform Plumbing Code should be used to determine the proper size and capacity of the interceptor or trap.

Grease interceptors are configured with two or three chambers to catch FOG and other debris before they exit to the sewer line. Interceptors are quite large, 1,500-2,000 gallons, and are usually buried outside the building they serve. A grease interceptor should have at least one manhole opening per chamber for inspection and cleaning, and should be inspected at least once a month.

Grease traps are smaller than grease interceptors and are usually found inside the building they serve under a sink. Grease traps are usually single chambered devices with baffles inside designed to slow the flow of wastewater. Their capacities are rated in gallons of flow and pounds of grease they hold. Being smaller, grease traps foul much easier when food grinders are used or kitchen practices utilize sinks for waste disposal. Grease traps should be inspected weekly; skimming of collected grease at that time is highly recommended.

A full-service cleaning by a licensed grease interceptor/trap service provider is recommended at least twice per year to ensure that the interceptor/trap is completely cleaned and inspected. Your business is ultimately responsible for the proper use and maintenance of the interceptor/trap.